Surve No. 682/1, Bhosari, Pune - 411039

We are Manufacturer, Supplier, Distributor, Trader, Importer, Exporter of Universal Testing Machines (UTM), Material Testing Machines, Universal Tester and our set up is situated at Pune, Maharashtra, India.

Incorporated Design Features to Enable High Accuracy

- Loading accuracy as high as ± 1%

- Straining roll autographic recorder supplied as standard to enable study of the behavior of materials.

- Motor driven threaded columns for quick & effortiess adjustment of lower crosshead to facilitate rapid fixing of test specimen.

- High reading accuracy due to large size and design of mechanical dial.

- Wide range of standard and special accessories, including load stabilizer (optional).

- Easy change from Plain to threaded and screwed specimen.

- Large effective clearance between columns enables testing of standard specimen as well as structures.

- Simple controls for ease of operation.

- Robust Straining frame of an extremely rigid construction.

- Safe operation ensured by means of safety devices.

- Fully enclosed and protected pendulum mechanism in mechanical machines.

STM Universal Testing Machine is designed for testing metals and other materials under tension, compression, bending, fransverse and shear load, hardness test on metals can also be conducted.

Principle of Operation :

Operation of the machine is by hydraulic transmission of load from the test specimen to a separately housed load indicator. The system is ideal since it replaces transmission of load through levers and knife edges, which are prone to wear and damage due to shock on rupture of test pieces. Load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the cylinder of the pendulum dynamometer system housed in the control panel. The cylinder of the dynamometer is also of self-lubricating design. The load transmitted to the cylinder of the dynamo meter is transferred through a leverage to the pendulum. Displacement of the pendulum actuates the rack and pinion mechanism which operates the load indicator pointer and the autographic recorder. The deflection of the pendulum represents the absolute load applied on the test specimen. Return movement of the pendulum is effectively damped to absorb energy in the event of sudden breakage of the specimen.

This consists of a hydraulic cylinder motor with chain sprocket drive and a table coupled with the ram of the hydraulic cylinder, mounted on to a robust base. The upper cross-head is rigidly fixed to the table by two straight columns. The lower cross-head is connected to two screwed columns which are driven by a motor. Axial loading by the provision of ball seat. A displacementelongation scale, with a minimum graduation of 1 mm for mechanical machine and 0.1mm for computerized machine is provided to measure the deformation of the specimen. Tension test is conducted by gripping the test specimen between the upper and lower cross - head and the table. The lower cross-head can be raised lowered rapidly by operation the screwed columns, thus facilitating ease of fixing of the test specimen.

Control panel :

The control panel consists of a power pack complete with drive motor and an oil tank, control valves, a pendulum dynamometer, a load indicator system and an autographic recorder.

Power pack :

The power pack generates the maximum pressure of 200 kgf/cm' The hydraulic pump provides continuous non-pulsating oil flow. Hence the load application is very smooth.

Hydraulic Controls :

Hand operated wheels are used to control the flow to and from the hydraulic system in regulating of oil flow to and from the hydraulic cylinder. The regulation of oil flow is infinitely variable. Incorporated in the hydraulic system is a regulating valve, which maintains a practically constant rate of piston movement. Control of this valve allows extensometer readings to be taken.

Testing - with Economy, Speed and Versatility Load Indicator System :

This system consists of a large dial and a pointer.

A dummy pointer is provided to register the maximum load reached during the test.

Different measuring ranges can be selected by operating the range selection knob.

An overload trip switch is incorporated which, automatically cuts out the pump

motor when the load range in use is exceeded.

Pendulum Dynamometer :

This units permits selection of favorable hydraulic ratios

producing relatively small frictional forces. Pressurised oil in the loading cylinder

pushes up the measuring piston which is constantly circulated to eliminate friction.

The dynamometer system is also provided with an integral damper and ensures

high reliability of operationT.he load transmitted to the dynamometer is transferred

through a pendulum to the load indicator.

Autographic Continuous Roll Load elongation Recorder :

This units is of the pen and drum type and is supplied as standard.

The horizontal motion of the pen produces the load ordinates of the diagram and

the drum rotation produces the extension ordinates, in the ratio of either 1:5 or 1:10

A continuous roll of graph paper is stored inside the drum and can be

easily replaced.

Universal Testing Machines are closely controlled for sensitivity, accuracy and calibration over each of its measuring ranges in accordance with the procedure laid down in British Standards 1610 : 1964 and IS 1828 1975 and BS 4449

Universal Testing Machines Comply with :

Grade "A" of BS: 1610 : 1964 and Grade 1.0 of I5-1828-1975

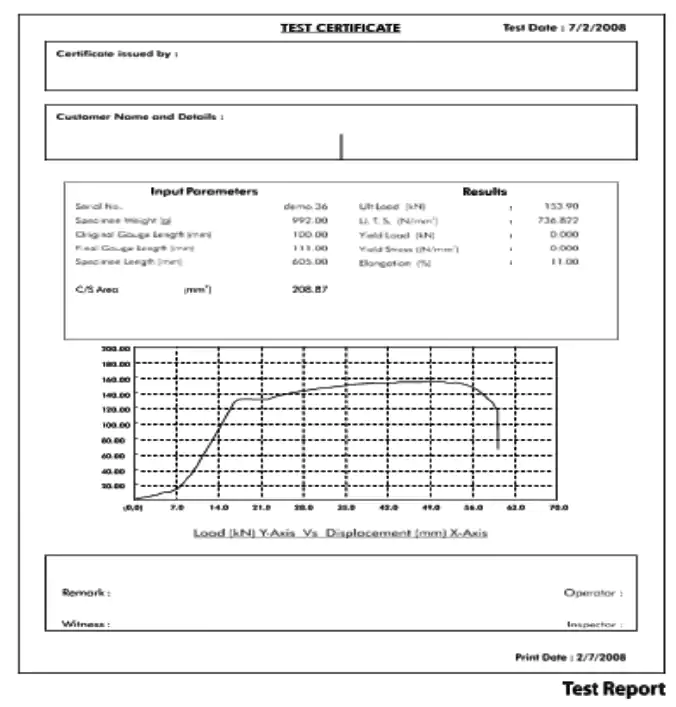

An accuracy of ± 1% is guaranteed from 20% of the load range selected to full reading. offers Electronic / Computerised Models of Universal Testing Machines of all capacities from 10 tonnes to tonnes. Feature :

- Micro processor based electronic panel.

- Precision strain Gauge type pressure transducer for load measurement.

- Rotary Encoder with rack for crosshead displacement / Extension indication.

- RS 232 COM Port for PC interface

- Data entry for specimen dimensions, Serial number, gauge length

- Unit selection for load, displacement

- Results include Load vs Displacement Curve, Maximum displacement, U.T.S., % Elongation, Young's Modulus & Proof Stress (if Extensometer is used).

Optional Accessories :

- X-Y Plotter Interface

- Load Stabiliser

- Crosshead Displacement Resolution of 0.01 mm

- Basic Evaluation Software

- Exhaustive Evaluation Software for Proof Stress Calculation

- Any Special Software / Requirement on Request

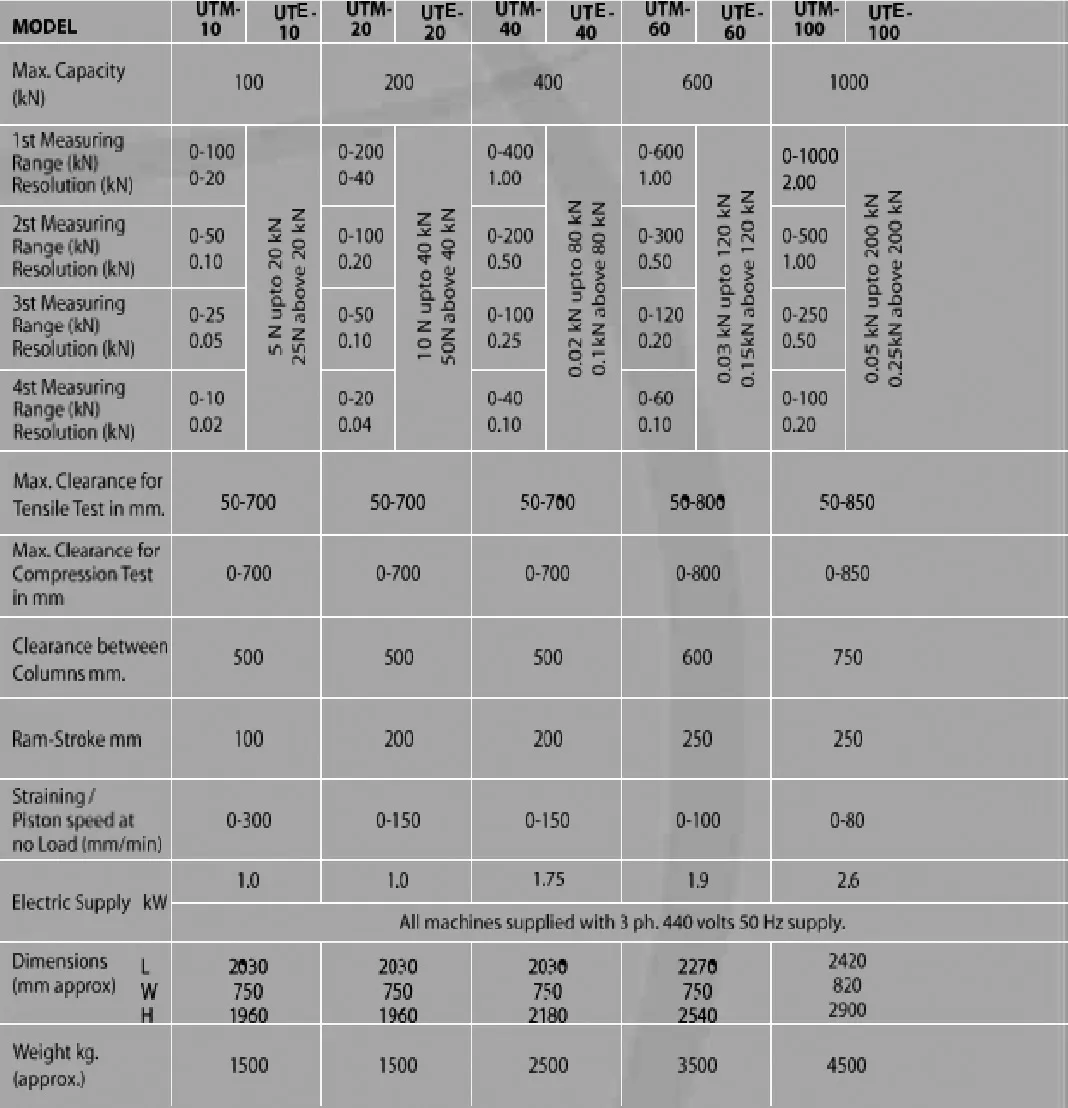

Specifications :

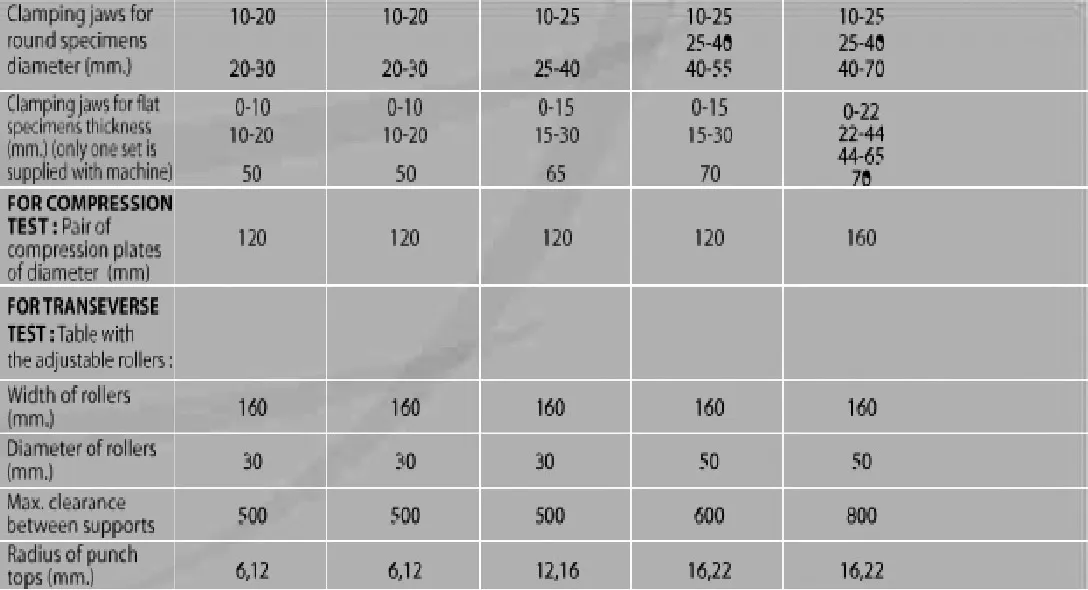

Standard Accessories :

recognizes that the most efficient way of testing is the testing software and the ease of operation of the software.

The Test Software has been ergonomically designed to suit the various needs of the customers as per their

requirements and operation of the software is extremely user friendly and the features are self-explanatory.

Features :

The introductory screen shows the features and display facility available at the first view of the software.

The various test modes includes the tests like:

- Tensile Testing

- Compression Testing

- Bend Test

- Shear Test

- Torsion Test

- Rubber / Textile Test

- Spring Test

- Extensometer Test

The bright, large and prominent display for the load and displacement adds to the readability value of the software and hence effortless observation of the online tests.

TEST SCREEN :

The enhanced display of the test screen displays the values of the load and displacement and the online graphs as it is generated during the tests. The selection of the scale so graph enables you to view the graph more prominently on the screen

The extensometer test screen incorporates the results of the normal Load Vs Disp. Test as well as the Load Vs Extension online graphical view simultaneously, a unique facility on its own. Alarms can be set up to remind the operator for disengaging the extensometer from the specimen : a unique safety feature of the UMI software for protecting the precise and delicate accessories.

STATISTICAL ANALYSIS :

This powerful tool enables the user to compare and study the results in statistical format. Most useful in places where the Batch Reports are studied for the production. This extraordinary feature has been designed keeping in mind the ever changing needs of the industry to achieve higher standards. This flexibility can be achieved with the software with an assurance of lifetime quality service and updates as per the latest industry standards. The test data can be analysed for following graphical interpretations :

- Water Fall Diagram

- Mean Deviation

- Frequency Distribution

- Skew Diagram

- Histogram

This helps the user to protect and save the test data of all the previous tests with the help of Password Protection feature.

Graph Tracing :

The resultant graph can be traced in various resolution of displacement with special zoom mode for time related behavior of the specimen

Additional Features :

include the facility to incorporate the Company Logo of the users at site on the Test Report and wide varlety of customization of the software features as per the needs of the customer.