Surve No. 682/1, Bhosari, Pune - 411039

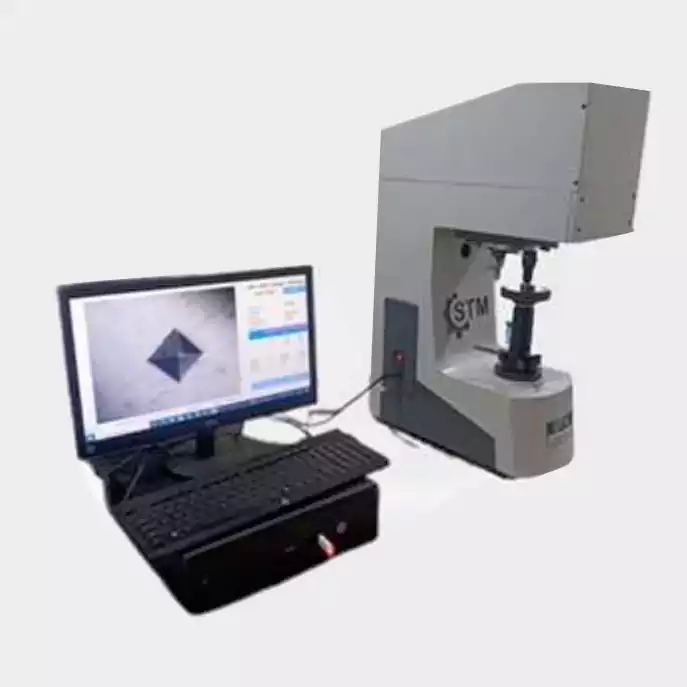

We are Manufacturer, Supplier, Distributor, Trader, Exporter, Importer of Load Cell Based Semi-auto Micro Vickers Testing Machines and our set up is situated at Pune, Maharashtra, India.

Our LMV-1 Micro Vickers Hardness Tester model is a unique product combining the robust mechanical welded structure design and load cell control system in the table-top version. This instrument has a servo controlled close-loops loop feedback control system, which controls the load within 1% accuracy of load cell capacity.

The machine’s mechanical and electronic system neither requires levelling of machine nor any specific

environmental conditions. This instrument consists of a one-touch calibration system with high linearity.

Suitable for harsh environment condition. (Temperature range: -10°c to 40°c)

The LMV-1 machine is powered by our own Software, equipped with easy-to-understand icons and workflows, Universal makes it simple to train users and set up tests, helping you maximize lab efficiency while minimizing costly errors. Self-guided software interface which will minimise errors in testing, and gives error free results. This machine based on INDUSTRY 4.0 having latest technology IoT SYSTEM.

MACHINE APPLICATION :

This models from the wide range of applications suitable for Labs, Heat Treatment Departments, Schools, Tool Rooms, Inspection Labs, Factories, etc. Suitable for all types of metals and non-metals, steel products, nonferrous materials, aluminium and soft alloys etc.

Also, can be used for plastics and composite materials like carbon fibre, Bakelite etc.

Technical Data :

| Scales | Micro-Vickers | Hv |

| Scales | Hardness Conversion | ASlM E140, DIN EN IS050150, DIN EN ISO 182265. |

| Test Forces | 0.010-2 kgf | 0.098-19.62 N |

| System | Load cell based, close loop force feedback system. | |

| Hardness Readings | Directly On Touch Screen With limit indications. | |

| Hardness least count | 0.1 Hv | |

| Load accuracy | as per standard <1% | |

| Load sampling rate | 400 samples per seconds | |

| Load cell capacity | 2 kgf | |

| Camera | 1.2 JV[p | |

| Field of view | 150 Microns | |

| Dwell Time | 00-99 Sec | |

| Connectivity | USB-3.0 for data output | |

| Connectivity | RJ45 for PC computer software connectivity for heat and batch repmt | |

| Spindle | Made of CAST-IRON, with a universal anvil attachment system. | |

| Max. Height of the Specimen (H) | 250mm | |

| Tln·oat depth (D) | 135mm | |

| Power Supply | Single phase, 50 Hz, 210-240 volts. | |

| Power Supply | Energy efficient (Power consumption only during test cycle) | |

| Machine Environment | -10°c to 40°c | |

| Dimensions | Machine Dimensions | 250x460x900mm |

| Dimensions | Packing Dimensions | 390x600x1100mm |

| Weight | Machine Net Weight | 100 Kg |

| Weight | Gross Weight | 120 Kg |

Standard Accessories :

| Sr.NO | DESCRIPTION | QTY |

| 1 | Main unit LMV -1 | 01 |

| 2 | Main unit cover (Anti dust cover for machine) | 01 |

| 3 | Anti-dust cover for main spindle | 01 |

| 4 | 0 100 mm round shaped test table | 01 |

| 5 | "V" shaped anvil up to 0 38 mm round job | 01 |

| 6 | Standard test blocks | 01 |

| 7 | Indenter | 01 |

| Micro-Vickers diamond indenter | 01 | |

| 8 | Power chord | 01 |

| 9 | Fuse 2 Amp | 02 |

| 10 | Allen key set | 01 |

| 11 | Screw driver | Ol |

| 12 | Rest pad | 04 |

| 13 | Clamping cone for safety | 01 |

| 14 | Machine Pen drive | 01 |